Design & Engineering

Modern Orthodontics has a complete in-house product design and engineering team to ensure direct supervision over the product quality and functionality at this initial production stage. Our design team has more than 20 years of collective orthodontic design experience with different 3D modelling softwares. This design team works under direct guidance of our founder Orthodontist Dr. Anil K Goyal who has a clinical experience of more than 23 years of exclusive orthodontic practice.

Modern Orthodontics has a complete in-house product design and engineering team to ensure direct supervision over the product quality and functionality at this initial production stage. Our design team has more than 20 years of collective orthodontic design experience with different 3D modelling softwares. This design team works under direct guidance of our founder Orthodontist Dr. Anil K Goyal who has a clinical experience of more than 23 years of exclusive orthodontic practice.

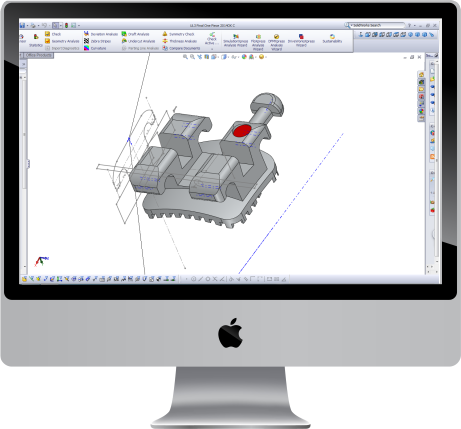

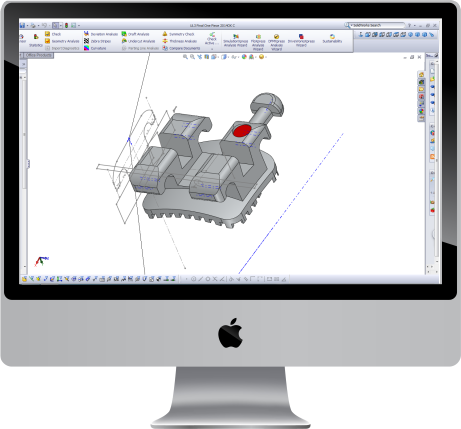

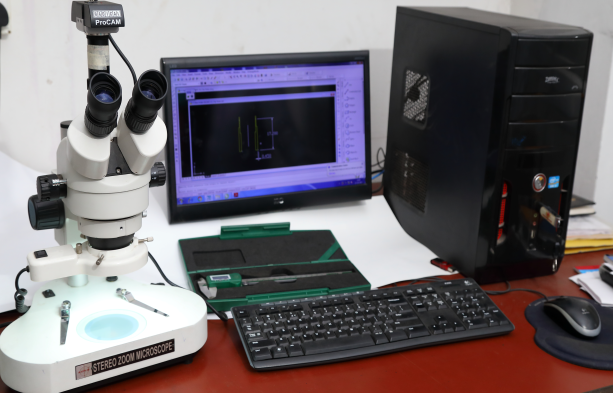

Design and Engineering is the first step in product development and is a strong foundation for manufacturing. Modern Orthodontics has got everything that is needed from a design and engineering point of view. We are very proud of our ultramodern tool room which is equipped with the best machines and equipment. All our molds and sheet metal tools are designed and manufactured in house using multiple CAD softwares. Our expertise in designing parts and tools give us an advantage over other market players as we do not have to rely on outside vendors for mold designing and tooling.

By combining more than 20 years of collective orthodontic design experience with our 3D modeling, we can get your products from paper to market quickly, efficiently, and at a competitive price. The use of CAD software is not only limited to the design of new products, its function in the design of molds is also very important. The new generation of 3D solid modelling softwares are equipped with highly developed tools that not only dramatically decrease the time it takes to design a mold, but also allow for the examination of the part's geometry, analysis simulation and the forecast of potential molding issues.

Draft analysis, thickness examination, undercut detection, geometry check and parting line recognition represent just a few of the parameters that can be obtained with new generation of CAD software. Moreover, it can also predict advanced tooling problems such as sink marks, knit lines and other cosmetic defects before any tools gets manufactured, thus saving both time and money.

Draft analysis, thickness examination, undercut detection, geometry check and parting line recognition represent just a few of the parameters that can be obtained with new generation of CAD software. Moreover, it can also predict advanced tooling problems such as sink marks, knit lines and other cosmetic defects before any tools gets manufactured, thus saving both time and money.

We understand that the most time-consuming and costly phase of plastic part production is in the design of the mold. With this in mind, we use our expertise to take the guesswork out of mold design by forecasting potential problems with the part's design and determining upfront whether a product concept is moldable. This allows revisions and modifications to be made before the project continues.

With a focus on quick yet thorough, extensive yet cost-effective mold design, we provide a complete solution to help manufacturers get their product concepts to market faster. We are proactive in concurrent engineering and design assistance and offer one of the shortest lead-times in the industry.

We love to take challenges and constantly strive to achieve minimum tolerances in our molds which reflects in the ultimate accuracy that we achieve in the parts geometry.

Modern Orthodontics has a complete in-house product design and engineering team to ensure direct supervision over the product quality and functionality at this initial production stage. Our design team has more than 20 years of collective orthodontic design experience with different 3D modelling softwares. This design team works under direct guidance of our founder Orthodontist Dr. Anil K Goyal who has a clinical experience of more than 23 years of exclusive orthodontic practice.

Modern Orthodontics has a complete in-house product design and engineering team to ensure direct supervision over the product quality and functionality at this initial production stage. Our design team has more than 20 years of collective orthodontic design experience with different 3D modelling softwares. This design team works under direct guidance of our founder Orthodontist Dr. Anil K Goyal who has a clinical experience of more than 23 years of exclusive orthodontic practice. Draft analysis, thickness examination, undercut detection, geometry check and parting line recognition represent just a few of the parameters that can be obtained with new generation of CAD software. Moreover, it can also predict advanced tooling problems such as sink marks, knit lines and other cosmetic defects before any tools gets manufactured, thus saving both time and money.

Draft analysis, thickness examination, undercut detection, geometry check and parting line recognition represent just a few of the parameters that can be obtained with new generation of CAD software. Moreover, it can also predict advanced tooling problems such as sink marks, knit lines and other cosmetic defects before any tools gets manufactured, thus saving both time and money.